We apply E-coat (cataphoresis coating) making coating thickness equal in every region of the wheel, thus combating corrosion for a longer period of time.

To allow the use of large disc brakes, it was necessary to move the valve from the inside of the disc to the outside. This prevents the breaking of the valve due to foreign substances (like mud, stones, rocks etc.) which may come from the external environment.

The enlarged air holes allow the wheel, brake and tyre systems to cool quickly which helps prolong the life of the brake system between scheduled maintenance.

Ventilation hole deburring: The burr around the air holes are deburred from inside and outside which prevents the formation of cracks in this area.

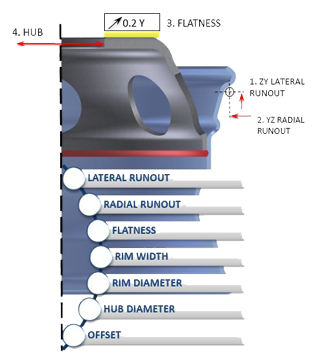

All critical dimensions are 100% guaranteed on every wheel with 'automatic measuring stands' that are positioned at the end of each production line.

Designs are optimized using FEA in order to obtain the lightest wheel in the market. We provide customized solutions to meet the needs of our customers.

A 4-digit number is engraved on each rim that enables backward traceability of the product.

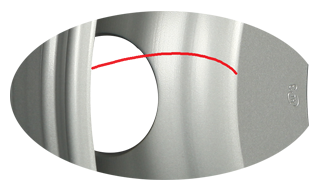

The disc of the wheel is produced by the CNC machines in millimeter sensibility using the flow forming method.

With the use of the rollers in CNC machinery, the steel is lengthened and tightened milimetrically. This process delivers a stronger wheel.

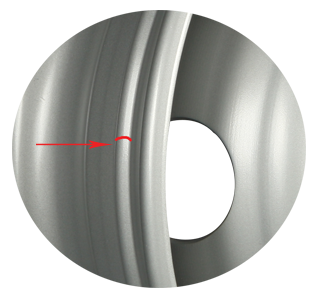

Welding is performed by a fully automatic welding machine and experts in this field ensure superior quality and workmanship supporting the longevity of the wheel life.

We manufacture our wheels using raw material accepted by international standards.